From Wind Tunnels to Space: Vacuum for Aerospace Research

MAULBURG, Germany - At the German Aerospace Center (DLR) in Göttingen, scientists are exploring the phenomena of compressible flow mechanics in Europe's largest and most powerful tube wind tunnel using a COBRA screw vacuum pump from Busch Vacuum Solutions. The goal is to make the aerospace of tomorrow safer and more efficient. The German Aerospace Center (DLR) in Göttingen is researching fluid mechanics phenomena, which are essential for adequately predicting the performance of supersonic aircraft. Source: DLR.Two accumulator tubes of more than 80 meters in length run over an open space next to the building and pass through the solid outer wall to the inside: The enormous dimensions of the research facility become clear as soon as you enter the site around the Institute of Aerodynamics and Flow Technology at the DLR in Göttingen. Inside, a giant vacuum vessel with a volume of 50 m3 is connected to the tubes. Detailed and fundamental studies are carried out there to investigate the fluid mechanics phenomena that are essential for adequately predicting the performance of supersonic aircraft. How can the aerospace vehicles of tomorrow become more environmentally friendly, safer and more efficient? And how can you use precise computer simulation of supersonic flight to evaluate new configurations while still in the design process? The scientists want to provide answers to these questions, and many others, with the tube wind tunnel. Vacuum technology from Busch is an indispensable part of these research projects. The large-scale research facility was opened in the 1950s. Göttingen-based physicist and flow researcher Prof. Hubert Ludwieg developed a revolutionary drive system for intermittently operating high-speed wind tunnels, which enabled studies with supersonic and hypersonic flows to be carried out. He called this principle a tube wind tunnel – which to this day is also known around the world as a "Ludwieg tube." In 1968, the Ludwieg Tube Wind Tunnel, Göttingen (RWG) was the first of these large-scale aerodynamic research plants in the world to be put into operation. It is still in use at the DLR to this day.Experiments at supersonic speedThe operating principle of the tube wind tunnel uses the interaction of pressure and vacuum, where the accumulator tubes serve as pressure vessels in which the air is compressed. To prevent air condensation in the ultrasonic nozzle, which occurs due to the strong expansion and the associated cooling of the air, the accumulator tubes must be heated to simulate high supersonic velocities. The accumulator tubes are connected to the ultrasonic nozzle via a quick-action slide valve. The measuring section is found at the end. This is where experiments are carried out. At the end of the measuring section is the vacuum vessel, which the vacuum pump is connected to. A vacuum slide valve between the measuring section and the vacuum vessel enables access to the measuring section as required. The vacuum vessel is evacuated using the vacuum pump. A COBRA NX screw vacuum pump from Busch Vacuum Solutions is used for this. ...Full story available on Benzinga.com

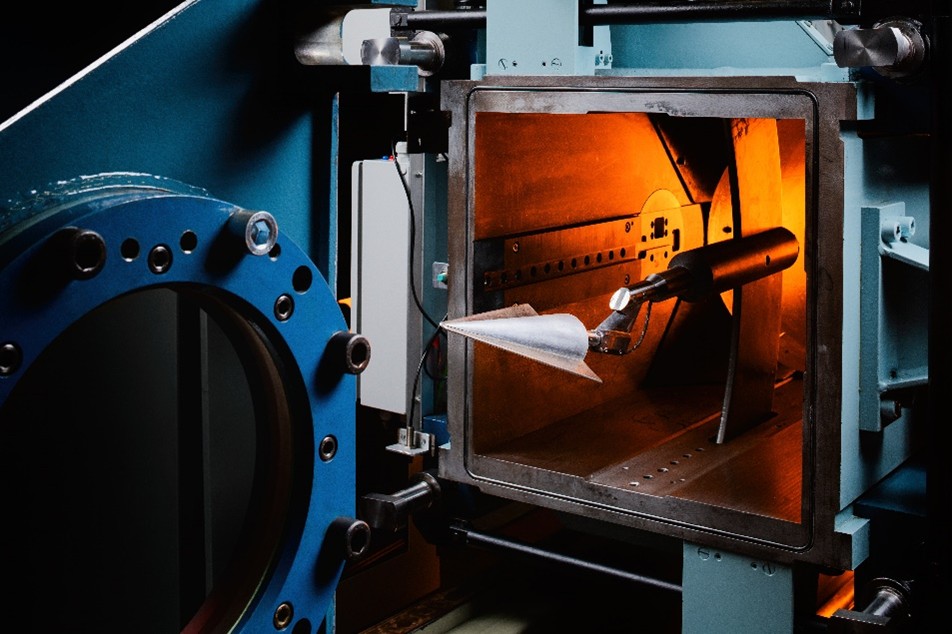

The DLR's Institute of Aerodynamics and Flow Technology in Göttingen houses this impressive facility. Two accumulator tubes, each stretching over 80 meters, dominate the landscape, hinting at the scale of the experiments conducted within. These tubes feed into a massive 50 m3 vacuum vessel, forming the core of the wind tunnel.

The research focuses on understanding fluid mechanics phenomena critical for accurately predicting the performance of supersonic aircraft. By simulating supersonic flight with precision, scientists aim to evaluate new aircraft configurations early in the design process. This allows for informed decisions that optimize performance, reduce environmental impact, and enhance safety.

The tube wind tunnel, a concept pioneered by Göttingen-based physicist Prof. Hubert Ludwieg, relies on the interplay of pressure and vacuum. The accumulator tubes act as pressure vessels, compressing air to simulate high supersonic velocities. To prevent air condensation in the ultrasonic nozzle, which occurs due to rapid expansion and cooling, the tubes are heated. A quick-action slide valve connects the accumulator tubes to the ultrasonic nozzle, leading to the measuring section where the experiments take place.

The vacuum vessel, connected to the measuring section via a vacuum slide valve, plays a vital role in creating the necessary conditions for supersonic testing. The COBRA NX screw vacuum pump from Busch Vacuum Solutions is essential for evacuating the vacuum vessel. This allows researchers to control and manipulate the airflow, mimicking the extreme conditions encountered during supersonic flight.

Originally opened in the 1950s, the Ludwieg Tube Wind Tunnel in Göttingen (RWG) was the first large-scale aerodynamic research plant of its kind and remains in operation at the DLR today. Its continued use highlights the enduring value of this technology in advancing our understanding of aerospace.